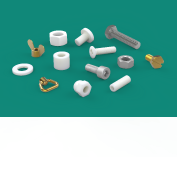

Technical Information Materials - Aluminium

Chemical, physical and mechanical characteristics of Aluminium

Pure aluminium is a soft, ductile material, which limit its use and application. The addition of alloying elements (mainly magnesium, silicon, copper, zinc or manganese) increases its mechanical properties considerably, leading to its widespread use in areas where a good relation between strength and weight and a good corrosion resistance are required.

One of the most common alloys with excellent characteristics is Al7075 (commonly referred as Ergal), which includes, magnesium and copper, giving it the highest mechanical characteristic of aluminum alloys.

Aluminium alloys, when heat treated, obtain a higher tensile strength and increased mechanical properties, such as impact, weight and torsion resistance, and they become competitive with some steels , but with a volume density approximately three times lower.

The main characteristics of aluminium that allow its widespread use in many different areas are:

- Lightness (about 1/3 compared to steel)

- Excellent workability on machines and excellent quality of surface finish

- Bright and aesthetically pleasing appearance

- Good corrosion resistance

- Good mechanical resistance

Al7075 is a light alloy which provides a high mechanical resistance as well as good vibration absorption, therefore it is used in a wide range of screws for aerospace and aeronautical applications, and also in the bicycle and motorcycle industries.

| Screws/Bolts | Washers | ||||

| Designation | P60 | P65

| P40 |

H14 |

Grade 3(h22) |

|

| ISO 209-2007 | AlZn5.5MgCu | AlZn5.5MgCu | AlMgSi | Al99,5 | AlMg3 |

| Grade | 7075 | 7075 | 6060/6101 | 1050 | 5754 |

| Heat Treatment ISO 2107:2004 | T6 | T73 | T8 | H14 | H26 |

| Manufacturing Process | - | - | - | Pressing | Pressing |

| Tensile Strength N/mm2 | 550 | 490 | 270 | 260 | 200 |

| Yield Strength N/mm2 | 460 | 420 | 240 | 210 | 280 |

| Elongation after rupture min% | 7 | 11 | 6 | 4 | 7 |

| Hardness HB | 160/185 | 146/169 | 95/105 | 72 | 63 |

Teknipart Ltd

Teknipart Ltd

Teknipart Ltd

Teknipart Ltd